Fence-blinds

Fence blinds

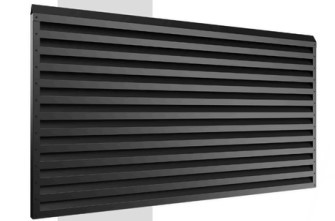

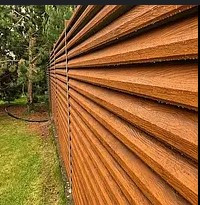

Sections with slats are used to fence a house, cottage, commercial property, parking, public areas. They protect from prying eyes and become part of landscape design. For arranging a courtyard/city area, ensuring privacy in a company.

Rolled steel products

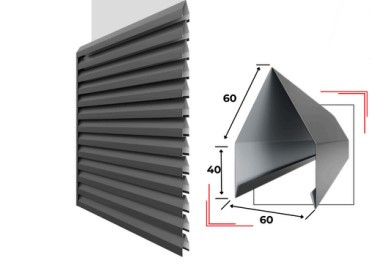

Metal sections are more reliable. Supporting structures made of profile give the fence additional rigidity. The frame space is filled with slats. During the profiling process, stiffening ribs are formed that prevent deflection under weight or wind load.

The advantages of such sections include not only mechanical strength, but also lower weight. Galvanization, polyester powder coating protect against corrosion in any climatic conditions. During installation, it is important not to damage the decorative layer, otherwise, when exposed to atmospheric precipitation, rusty spots appear that require cleaning and repainting. Compared to wooden ones, the cost is higher, but the blind fences do not require maintenance. Even after many years, they look like new.

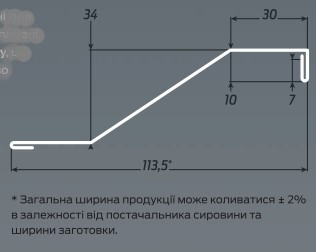

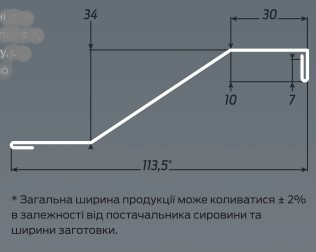

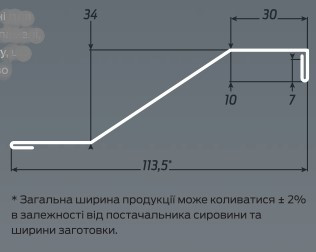

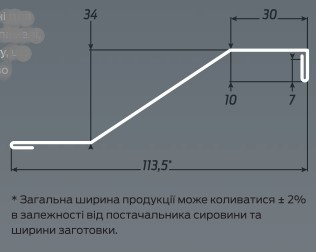

Dimensions

Flexibility in choosing parameters determines the appearance of the fence. The standard is considered to be the height of sections up to 2.10 m. At the same time, the width can reach 2.5-3 m. Such spans are convenient for installation. The longer the slats, the fewer posts. This reduces the cost of purchasing materials and labor.

The thickness of the metal slats depends on the type of fence and directly affects its strength. Manufacturers use different rolled metal for the fences.

Advantages

Shutters are suitable not only for perimeter fencing, but also for the manufacture of wickets, folding doors and gates. Compared to traditional solutions, shutter fences have a number of advantages.

- The inclined arrangement of the segments ensures ventilation and eliminates visibility from the outside. However, it is convenient to observe the street and neighbors from the yard.

- They do not prevent the sun from reaching the plants and eliminate the greenhouse effect after rains.

- Rolled edges protect against scratches.

- The aesthetic appeal of the fence favorably distinguishes the site.

- Regardless of the thickness of the metal, the strips weigh little, thanks to the stiffening ribs, and last a long time.

- In case of local damage, the section can be repaired without replacement.

- Stylistic combination with all architectural styles.

The polymer layer and powder paint protect the metal from rusting, and the wood from drying out and warping.

Color solutions

Technological features of production allow to paint segments in any shades from the RAL palette. In the line you can find options with one-sided coating and presentable appearance. Many are attracted by double-sided sections in the same design from the yard/street side.

Installation features

Professional installation is essential for the durability of steel structures. Adjusting the slats at the factory simplifies and speeds up installation. Various schemes are used for fastening. In the classic version, they are fixed with comb profiles, aluminum/PVC brackets to the posts at reinforced points, and clicked with locks.

During installation, a lot of time is spent on burying the supports that take the load. The sections are also hung on columns, pillars made of brick, concrete, metal with gaps. To mask the fasteners, they are covered with inserts, which additionally even out the distance between the segments.