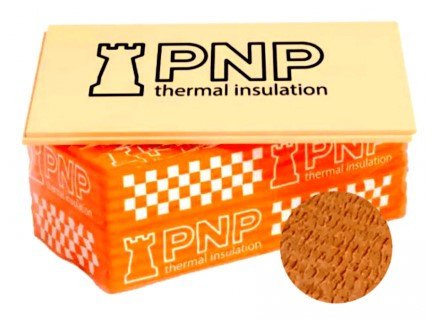

Polystyrene PNP GENERAL 150 5x58.5x118.5 cm 8 pcs/pack T15

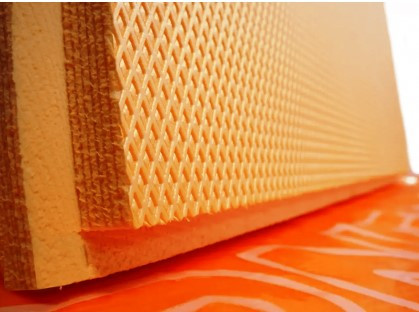

Extruded polystyrene PNP 150 MG is a highly effective heat-insulating material of the latest generation, produced by the extrusion method from general-purpose polystyrene. In the finished form extruded polystyrene foam - this is a hard foamed thermoplastic of a light pink color with a smooth or milled surface.

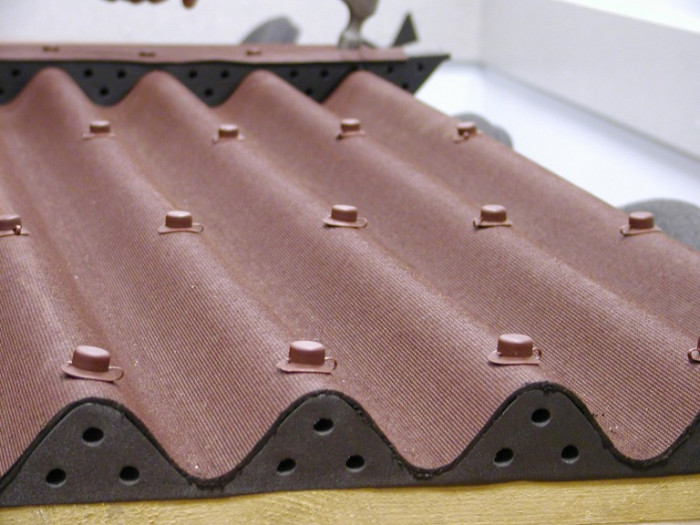

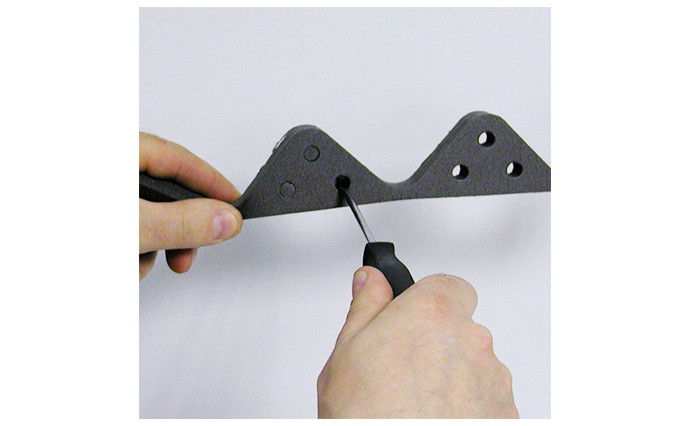

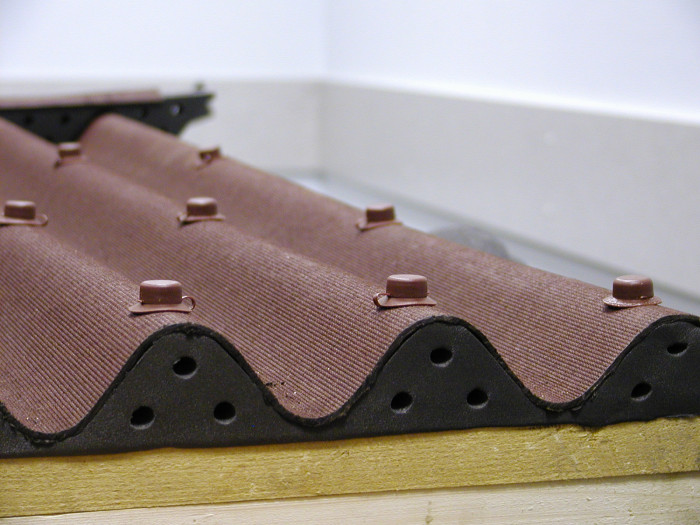

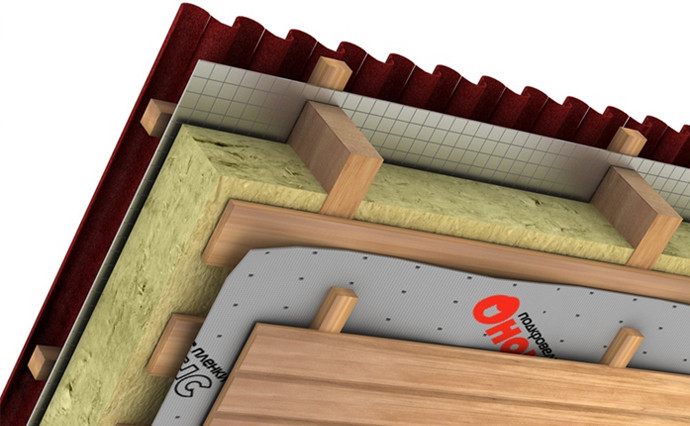

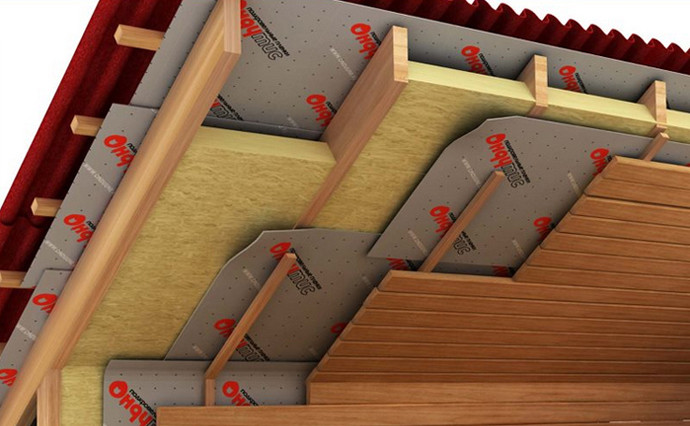

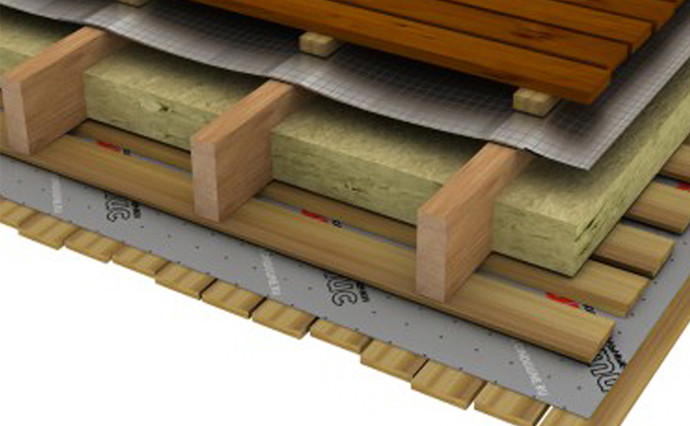

Styrofoam PNP 150 MG made of extruded polystyrene foam, used for insulation of foundations, pipelines, roofs, underfloor heating, wall, foundation etc.

PNP XPS 150 MG - these modern heat-insulating materials made of extruded polystyrene increase energy efficiency and extend the service life of assembly objects in all branches of construction.

Extruded polystyrene PNP XPS 150 MG:

A special type of slabs intended for use under plaster or for plaster work. The plates have a milled, rough surface with grooves or embossing, which improves adhesion with glue when plastering with the surface of the material.

Production of extruded polystyrene PNP XPS 150 MG:

Extruded polystyrene PNP - effective thermal insulation for all areas of construction. Due to its high parameters, extruded polystyrene is widely used in residential, industrial, private, agricultural and public buildings. The material is also necessary for the insulation of pipelines in plumbing systems of a warm floor and as a basis for covering automobiles, railways, runways, and building houses.

Advantages of extruded polystyrene PNP XPS 150 MG:

- Thermal conductivity of extruded polystyrene PNP XPS 150 MG:

Constantly low thermal conductivity of PNP ensures consistently high thermal protection of the structure throughout the entire period of use of the object, regardless of operating conditions.

- Safety of extruded polystyrene PNP XPS 150 MG:

XPS PNP does not release harmful substances into the air, such as phenols or isocyanates, and does not contain hexabromocyclododecane (HBC).

- Biostability of extruded polystyrene PNP XPS 150 MG:

XPS PNP is not a nutrient medium for the growth of bacteria, mold and other harmful microorganisms, ensuring the safety and durability of the object as a whole.

- Moisture resistance of extruded polystyrene PNP XPS 150 MG:

Due to the closed cellular structure, XPS PNP does not absorb water and retains all the declared properties throughout the entire service life of the structure, even in the case of direct long-term contact with water.

- Ecologically clean extruded polystyrene PNP XPS 150 MG:

XPS PNP produced on modern equipment using innovative non-fractional technologies.

- Durability of extruded polystyrene PNP XPS 150 MG:

The service life of the material is more than 50 years.

Main properties of extruded polystyrene PNP 150 MG:

- Extruded expanded polystyrene PNP 150

- Low thermal conductivity

- Zero water absorption is a homogeneous structure

- High compression and bending strength

- Absolute bioresistance

- Durability

- Environmental friendliness

Technical characteristics of extruded polystyrene PNP 150 MG:

- Density - 150 kg/m3

- Packaging – 8 pcs

- Thickness – 20, 30, 40, 50, 100 mm

- Thermal conductivity - Low

- Environmental safety of the material - Safe

- The length of the material is 1185 mm.

- Width – 585 mm.

- Production - Moldova

Production of extruded polystyrene foam PNP 150 MG:

- Extruded polystyrene PNP MG 20mm 1185x585 (pack of 20) 0.01387 m3/piece

- Extruded polystyrene PNP MG 30mm 1185x585 (pack of 13 pcs) 0.0208 m3/pc

- Extruded polystyrene PNP MG 40 mm 1185x585 (pack of 10) 0.02773 m3/piece

- Polystyrene extruded PNP MG 50mm 1185x585 (pack of 8) 0.03466 m3/piece

- Extruded polystyrene foam PNP MG 100mm 1185x585 (pack of 4) 0.06932 m3/piece

- Extruded polystyrene without quarter PNP MG 30 mm 1185x585 (pack of 13 pcs) 0.0208 m3/pc

Material width | 0.585 m |

Product thickness | 50 mm |

Country of manufacture | Moldova |

Length | 1.185 m |

Unit of measurement | packaging |

Flammability group | G1 |

Width, m | 0.585 |

Help other users with the choice - be the first to share your opinion about this product.