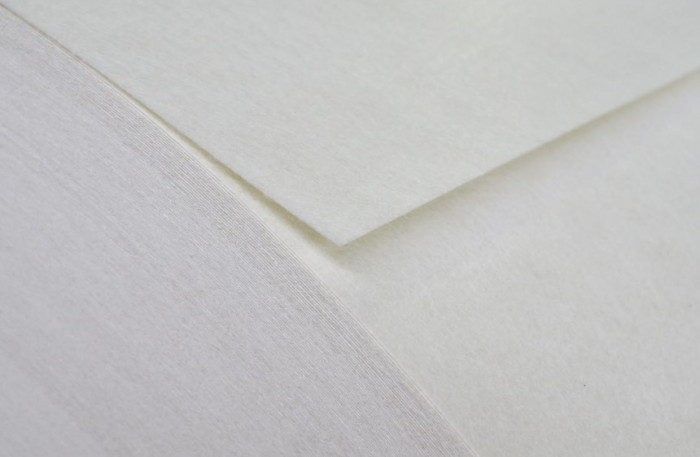

RUNO calendered geotextile

Polyester geotextile fleece (TU U 17.5-25178147-002-2004) is a non-woven fabric made of polyester fiber by needle punching. This is a geotextile made of polyester fibers using thermal bonding using staple technology.

Non-woven geotextile fleece has a number of excellent qualities that make it the best filler for drainage in combination with sand.

| Geotextile K100 |

|

| Density, g/m2 |

100 |

| Strength limit along the length/width is not less than kN/m |

2.8/2.8 |

| Relative elongation at break, not less than % |

30/50 |

| Thickness at a load of 2 kPa, mm |

0.4-0.6 |

| Roll height, m (meters) |

250/300 |

| Geotextile K150 |

|

| Density, g/m2 |

150 |

| Strength limit along the length/width is not less than kN/m |

4.0/3.8 |

| Relative elongation at break, not less than % |

30/50 |

| Thickness at a load of 2 kPa, mm |

0.5-0.8 |

| Roll height, m (meters) |

200 |

| Geotextile K200 |

|

| Density, g/m2 |

200 |

| Strength limit along the length/width is not less than kN/m |

5.4/6.0 |

| Relative elongation at break, not less than % |

40/60 |

| Thickness at a load of 2 kPa, mm |

0.8-1.1 |

| Roll height, m (meters) |

150 |

| Geotextile K250 |

|

| Density, g/m2 |

250 |

| Strength limit along the length/width is not less than kN/m |

7.2/9.1 |

| Relative elongation at break, not less than % |

40/60 |

| Thickness at a load of 2 kPa, mm |

1.3-1.8 |

| Roll height, m (meters) |

100 |

| Geotextile K300 |

|

| Density, g/m2 |

300 |

| Strength limit along the length/width is not less than kN/m |

8.6/10.1 |

| Relative elongation at break, not less than % |

50/65 |

| Thickness at a load of 2 kPa, mm |

1.9-2.4 |

| Roll height, m (meters) |

100 |

About the importance of using geotextiles in various spheres of activity

Despite the fact that geotextile fleece is a relatively new material, many areas of production cannot do without it.

Fleece geotextile is used in the construction of roads, sidewalks, runways, when laying underground communications, when arranging drainage systems, in agriculture, horticulture and landscape design, and in many other areas.

The practical, universal and easy-to-use material reduces the cost of construction and extends the service life of exploited sites and structures.

We present on the market Ukrainian-made geotextiles under the trademark "Runo". Geotextile "Fleece" is a non-woven material that is ideally suited as:

- a separating layer between sand and gravel to prevent their mixing;

- filter layer when installing drainage systems and winding drainage pipes;

- It provides waterproofing protection against mechanical damage.

Geotextile "Fleece" is easy to install. The rolls are small in size and light in weight, which reduces transportation and storage costs, as well as labor costs. It does not absorb moisture, when used in wet conditions, the weight of the rolls remains unchanged.

Geotextile Runo K is a calendered (or needle punched) geotextile intended for distribution, reinforcement and filtration. It is environmentally safe, does not rot, is not affected by insects and rodents, is resistant to thermal oxidative aging, chemically resistant, resistant to high temperatures (-60°С—+110°С), has high tear and puncture resistance.

Areas of use:

— construction of foundations;

— construction and reconstruction of roads;

— construction of drainage structures, hydrotechnical structures;

— used for filtration and reinforcement of various types of soil layers and embankments, and also used for landscape design.

Advantages of nonwoven geotextiles

Geotextile is a high-tech, practical and inexpensive material, which is distinguished by its strength and resistance to aggressive environments. The density of the material is selected based on operating conditions.

- high modulus of elasticity, which provides shock absorption and softening of the shock load on the horse's back and legs during jumping, reduces injuries during work;

- high heat resistance and chemical inertness, resistance to aggressive biological effects;

- environmentally friendly material that does not cause allergic reactions;

- it is not subject to decay, mold and fungi do not develop in it;

- resistant to sunlight, rodents and insects ignore it;

- A reliable and durable material that retains all its properties for 15-20 years, both outdoors and indoors.

- filtering ability due to the specific structure of the material, which excludes the ingress of soil particles into the pores and their clogging;

- high resistance to mechanical damage.

Application of geotextile fleece for strengthening slopes

When carrying out improvement works, they often face such a problem as a slide or collapse of weak soil. Thus, weak and unstable soil should become a stable and durable surface capable of resisting the negative impact of ground and rainwater.

If earlier this problem was solved with great efforts, now there are simple and affordable ways to solve it. This can be achieved by using a material such as geotextile fleece.

The good water permeability of the geotextile fabric allows water to pass freely, but at the same time prevents the soil from being washed away. In combination with their properties, geotextiles and soil successfully resist the forces of gravity. In addition, this material protects the soil from frost and prevents mixing of layers in the soil during the period of water rise.

Needle-punched geotextile fleece with a density of at least 200 g/sq m is most often used to strengthen slopes. m. Thanks to the great thickness and chaotic interweaving of the fibers with each other, the needle punched fabric reliably holds loose materials and prevents the destruction of slopes.

With the help of a synthetic canvas, you can fix slopes with an angle of inclination of up to 60 degrees and prevent the top layer of soil from sliding off them. On such slopes, you can plant annual and perennial plants, as well as small shrubs. For planting trees, it is recommended to use geotextiles in combination with a geogrid, which will allow you to create sufficiently large flat terraces suitable for the root system of the tree.

The process of fixing geotextile can be done in different ways. On small slopes, the canvas can be fixed with pegs or stones. When creating a structure from several layers, the geotextile fabric is additionally fixed with the help of large gabions or anchors.

Country of manufacture | Ukraine |

Weight, kg | 91 |

Unit of measurement | sq.m. |

Brand | Aquaizol |

Width, m | 3.03 |

Length, m | 100 |

Help other users with the choice - be the first to share your opinion about this product.