Metal tile VENICE modular

Technical parameters of VENICE modular:

- Total module width [mm] – 1190

- Usable module width [mm] – 1150

- Embossing height [mm] – 35

- Wave height [mm] – 26

- Total height [mm] – 61

- Total module length [mm] – 736

- Effective module length [mm] – 700

- Wavelength [mm] – 350

- Width between wave crests [mm] – 230

- Effective area of the module [m²] – 0.805

- Module weight [kg] – max 3.7

- Number of effective m² on a pallet [m²] – 281.75

- Number of modules on a pallet [pcs.] – 350

- Number of layers/modules in a layer [pcs.] – 10/35

- Zinc coating [g/m²] - min 275

- Pallet size [mm] – 1200 x 800 x 940

- Pallet weight [kg] - ~1200

- Metal thickness [mm] – 0.5

- Minimum roof slope (recommended) – 16.8° (30.2%)

Ideal for classic homes.

5 lower waves and 6 peaks of Venecja emphasize the beauty of classic houses.

Multiple award-winning

The Gold Medal of MTP BUDMA 2014, the Gold Medal of MTP BUDMA 2017, the Recommendation of the Polish Roofers Association and the Golden Helmet Emblem of the INTERBUD Fair are just some of the awards that Venecja has received.

Even a 50-year warranty

Venecja is durability and safety for many years. Depending on the coating used, the warranty for this product is 20, 30 or 50 years.

Easy and quick installation

Factory-made mounting holes reduce the time spent on the roof. They also allow you to precisely connect the modules and adjust the entire slope after they are connected. That's not all. The roofing crew can work on several slopes at the same time. Our solutions are so good that we have patented them.

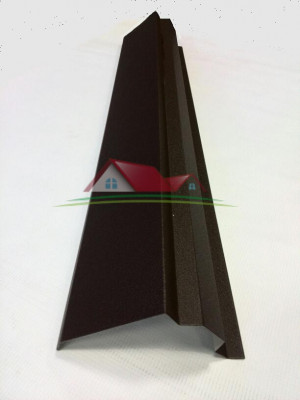

Elegant finish to your roof

Specially made for Venecja roofing modules, the ridge with its exquisite original finishes complements and once again emphasizes the aesthetics of the roof. Optional elements for Como are Budmat's own innovative solution that overcomes another technological barrier in the steel processing process.

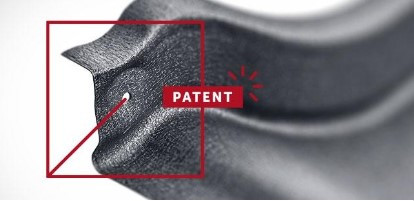

Prepared factory holes and 3d calibration - locks with stamped “cups”

This is our patent for roofing. Venice is a pioneer in the field of simple and intuitive and easy installation

Patented stiffener shape solution

Thanks to which the transverse connections on the roof become invisible, and the module acquires additional increased rigidity. We have successfully managed to combine aesthetics with strength

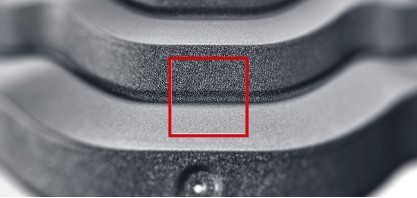

Bent bottom edge of the module

A solution that ensures better water drainage from the roof slope, preventing its accumulation on the surface. Also, the bend makes the transverse connection of the modules completely invisible.

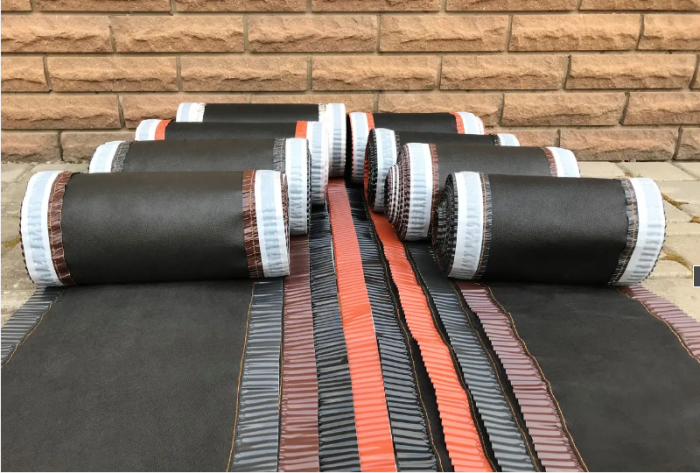

Coatings and colors

X-MATT (50 year warranty*)

GreenCoat Crown BT

The polymer coating is manufactured by the world-class Swedish steelworks SSAB. Now even more environmentally friendly. Thanks to a unique global patent, a significant part of the traditional petroleum ingredients have been replaced with Swedish rapeseed oil. The increased coating efficiency makes the GreenCoat® high-quality steel range an environmentally friendly offer of organically coated steel for construction. We are the only company in Europe to have a written guarantee from SSAB for color repeatability. The polymer coating belongs to the category of anti-corrosion coatings that comply with the EN 10169 standard. The polymer coating ensures a long product life, with increased resistance to mechanical scratches (sandblasting) and resistance to UV radiation. The high corrosion resistance characteristics of the X-Matt polymer coating have been confirmed by tests conducted in aggressive marine and industrial environments. The minimum zinc content in the metal shell is over 275 g/m². X-Matt polymer coating is a combination of strength, reliability and beauty.

*the warranty is provided under the conditions described in the warranty sheet, subject to the warranty being registered in the Budmat system by the distributor (presentation of the warranty card with the assigned number upon registration is a necessary condition for exercising the rights arising from the warranty provided).

D-MATT Plus (40 years warranty*)

The coating is produced by the world's largest steel producer - ArcelorMittal. We are the only company in Europe to have a written guarantee from SSAB for color repeatability. The D-Matt coating provides high strength and resistance to corrosion and scratches. Here are its most important technical parameters: decorative coating thickness: 35 microns; coating adhesion (T-bend): ≤ 1 T; resistance to bending cracking (T-bend): ≤ 2 T; impact resistance: 18 J; scratch resistance (Clemen): ≥ 1.5 kg; corrosion resistance: category RC3; resistance to ultraviolet radiation: QUV test (UVA + H2O) (2000 hours). The minimum zinc content in the metal shell is more than 275 g/m². If you are looking for a roof with a beautiful, matte and grainy structure, D-Matt is for you.

*the warranty is provided under the conditions described in the warranty sheet, subject to the warranty being registered in the Budmat system by the distributor (presentation of the warranty card with the assigned number upon registration is a necessary condition for exercising the rights arising from the warranty provided).

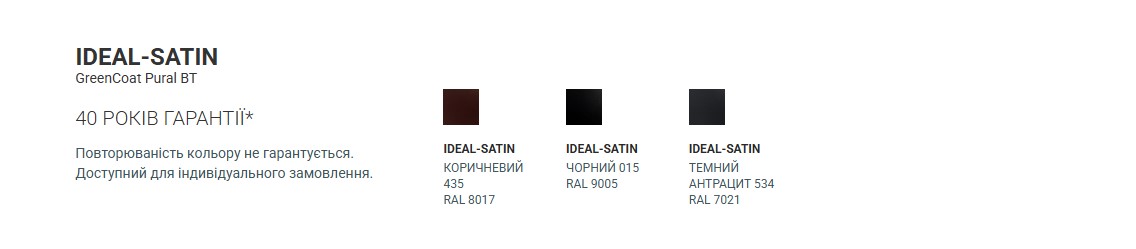

IDEAL-SATIN (40 years warranty*)

GreenCoat Pural BT

Another coating in the offer, produced by the world-class Swedish steelworks - SSAB. BT's patented solution contains a significant amount of Swedish rapeseed oil in the coating instead of petroleum ingredients - for a more environmentally friendly environment. The optimally selected chemical composition of the coating and the use of its thickness of 50 microns ensure resistance to weather conditions, which provides excellent resistance to corrosion and UV radiation. The delicate texture makes the surface very resistant to abrasion and wear. The back of the module is covered with a two-layer coating in gray, which further enhances corrosion resistance. The coating belongs to the category of anti-corrosion coatings according to EN 10169. Excellent forming properties allow bending at temperatures down to -15 °C.

*the warranty is provided under the conditions described in the warranty sheet, subject to the warranty being registered in the Budmat system by the distributor (presentation of the warranty card with the assigned number upon registration is a necessary condition for exercising the rights arising from the warranty provided).

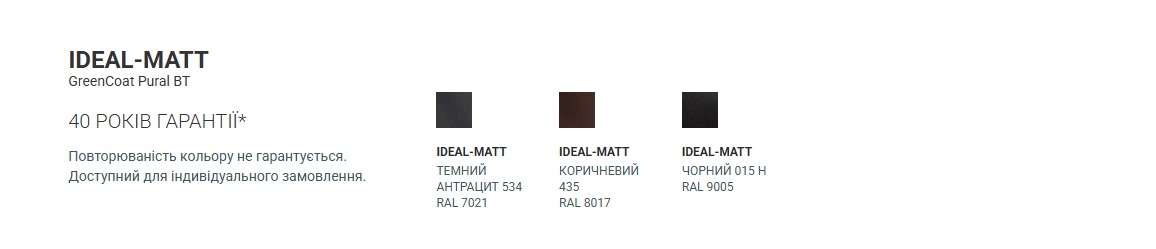

IDEAL-MATT (40 years warranty*)

GreenCoat Pural BT

Another coating on offer, produced by the world-class Swedish steel mill SSAB. The patented BT solution incorporates a significant amount of Swedish rapeseed oil into the coating instead of petroleum ingredients - for a more environmentally friendly environment. GreenCoat® from SSAB is designed to operate in the harshest climates on earth, GreenCoat Pural BT is the benchmark for polymer-coated steel products for roofing applications where durability is most needed. It offers a high level of durability for roofing applications such as profiled metal tiles. GreenCoat PLX Pural BT is optimized for harsh operating environments, with a coating thickness of 50 microns, which successfully resists aggressive weathering, resulting in the highest UV resistance (Ruv5 for a matte appearance) and corrosion resistance class (RC5+). The delicate texture makes the surface very resistant to abrasion and wear. The reverse side of the sheet is covered with a two-layer coating in gray, which further enhances corrosion resistance. The coating belongs to the category of anti-corrosion coatings according to EN 10169. Excellent forming properties allow bending at temperatures down to -15 °C.

*the warranty is provided under the conditions described in the warranty sheet, subject to the warranty being registered in the Budmat system by the distributor (presentation of the warranty card with the assigned number upon registration is a necessary condition for exercising the rights arising from the warranty provided).

Wave height | Medium |

Guarantee | 25 years, 35 years old, 50 years |

Sheet width | 1130 mm |

Zinc coating | 275 g |

Wave step | 350 mm |

Product thickness | 0.5 m |

Unit of measurement | sq.m. |

Flammability group | NG |

Length, m | 0.736 |

Length | 0 m |

Help other users with the choice - be the first to share your opinion about this product.